Search

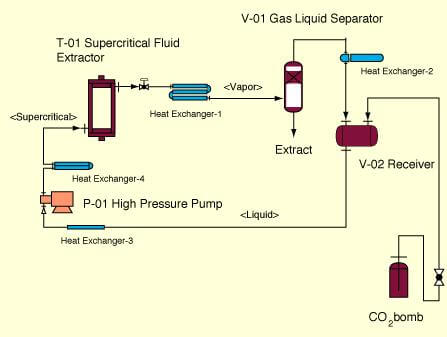

The raw material in powder form is fed to the extractor. We are committed to plant extract wholesale. The liquid carbondioxide from the CO2 tank is precooled by passing it through the precooler. This precooled liquid carbon dioxide is then pressurized by means of a positive displacement plunger pump to a pressure above the critical pressure of CO2 (i.e. 73.8 bar). High pressure liquid CO2 is then heated above the critical temperature of CO2 (i.e 31 °C) by passing it through preheater. CO2 which is now in the supercritical state enters the extractor in which the raw material is loaded. The SCCO2 dissolves substances on the basis of solubility, depending on operating conditions. The SCCO2 with soluble extracts enters the separators where the pressure & temperature are reduced sequentially so that solubility decreases & extract precipitates in the separators. Finally the clean CO2 without any traces is recycled back to the CO2 tank via condenser. Choose Kaiping as your botanical extract manufacturer.

Extract with delicacy & freshness close to natural

High potency of active components

Longer shelf life extracts

Eco-friendly & green technology with no residual solvent & effluents

High flexibility of process conditions

Simultaneous fractionation of extracts

High yields compared to solvent extracted products

Low batch times for extraction

Recycling of CO2

Low operating cost

Carbon dioxide is generally regarded as safe (GRAS) for food products

Inexpensive & easily available

Non-toxic, non-flammable and inert to most materials

Extraction of natural products such as spice oil & oleoresins, flavors, fragrances, colors

Decaffeination of tea & coffee

Production of uniform &ultra fine particles

Supercritical CO2 (SCO2) textile dyeing of fabrics

Supercritical CO2 (SCO2) cleaning of high precision metal components

Drying of aerogels